Efficient processing of grinding sludge

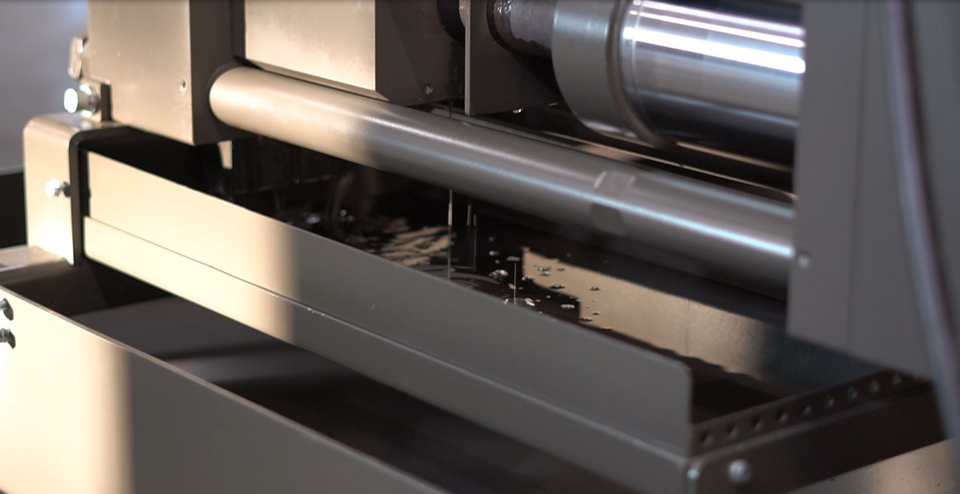

Our grinding sludge press forms briquettes from grinding sludge, recovering expensive cooling lubricants, such as oil or emulsion, in the process. These may actually account for more than 50% of the starting material.

The special briquetting technique used for grinding sludge is based on a special construction, developed by RUF, which has been technically adapted to deal with this particularly abrasive material. Due to its compact structure, the grinding sludge press can easily be incorporated into existing production processes and is suitable for 24h operation.

Advantages

- Recovery of expensive cooling lubricants – oil or emulsion

- Reduction in the amount to be disposed of

- Savings in logistics and transport

- Compact construction

- More than 35 years’ experience

Briquetting grinding sludge – recovering cooling lubricants

In addition to the recycling of grinding sludge, the recovery of cooling lubricant also results in significant savings. Costs are cut to a considerable degree thanks to the reduction in the amount of grinding sludge to be disposed of. Grinding sludge briquettes may also be classed as “non-hazardous waste”, although the agreement of the local authorities needs to be obtained.

Briquetting ensures a more sustainable, cleaner workplace. Depending on customer requirements, we offer grinding sludge presses for throughputs between 40 and 350 kg per hour.

Patrick Groth Foundry manager at HMT Höfer Metall Technik GmbH & Co. KG, Germany

“The RUF machines have been working very reliably since their commissioning. They are well-engineered and highly recommendable.”

Johann Dietl Head of CNC manufacturing at Zollner, Germany

"We are thoroughly satisfied with this equipment and are considering an expansion of its use."

David Kubis Order processing and purchasing at Alcutec, Germany

"This is the perfect solution to our handling and space problems. And the waste aluminium in the compact briquette shape – largely cleaned of the cooling lubricant emulsion – achieves a higher profit when sold on ."

Markus Weber Production Leader GFC AntriebsSysteme GmbH, Germany

"The briquetting system works completely without problems and had already amortised itself after two years.”

Stephan Diehl Executive SWG Metallverarbeitung und Montagetechnik GmbH, Germany

“We are very satisfied with the RUF Briquetting system. The investment has definitely paid off.”

Georg Reuss Executive Georg Reuss, Germany

"First and foremost I am impressed by the good price-performance ratio, the quality and the reliability of the machines. Besides I truly appreciate the excellent personal relationship I have experienced with the family business and their Senior Director Hans Ruf from day one."

Rolf Peter Leuchtmann Master Craftsman Final Machining Department, Georg Fischer Automotive Foundry, Germany

"The RUF briquetting press has been generating profits since day one, thanks to its good price-performance ratio, an appropriate financing plan and the savings it makes possible."

Lena Kozmenkova Executive SIA RMP, Latvia

"Our collaboration with company RUF has started in 2002 and has been successful through all these years. RUF is not just a world known machinery producer name and the leader in briquetting technologies market. RUF is your trustful business partner as it has been a reliable and supporting partner for us during both – periods of the sales peaks and during market depression. It’s our luck to have the same business philosophy with our main business partner – the RUF company. When both of you have the same aim, you achieve it faster!"

Wayne Carracher Managing Director Recycling Technologies Group Pty Ltd Australia

"We do not have one unsatisfied customer with a RUF machine – and we have sold some 40 systems here in Australia and New Zealand. That in itself speaks volumes for the RUF company and its equipment. In our opinion the RUF briquette press cannot be matched from a performance basis. Although it is more expensive than most competing machines from a capital cost point of view, the ongoing trouble free performance and maintenance of the RUF machines put them well ahead of the opposition."