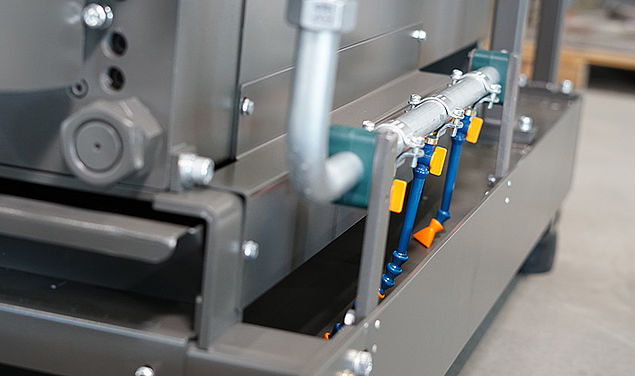

RUF 7.5-22 for grinding sludge Briquetting press for grinding sludge with slider

The advantages for you at a glance:

- Recovery of expensive cooling lubricants

- Volume and weight reduction

- No risk to water or soil from run-off of cooling lubricant

- Briquettes with defined residual moisture

- Fully automatic 24h operation possible

- Amortisation period can be extremely shortt

Increased value through briquetting of grinding sludge

With our briquette presses from the RUF 7.5-22 series, you can briquette the grinding sludge that has been produced and recover the expensive cooling lubricants that it contains. As a result of briquetting, the quantity to be disposed of also falls significantly and the briquettes have a defined residual moisture. Disposal costs are thereby reduced. With a quantity of only 10 to 30 tonnes of grinding sludge per year, the briquette press can pay for itself in less than 12 months!

Technical data RUF 7.5-22 for grinding sludge

| Max. throughput rate (kg/h) Grinding Sludge | 45-400 |

|---|---|

| Power (kW) | 7,5-22 |

| spec. Pressure, max. (kg/cm²) | 2.000 - 3.000 |

| briquette formats (mm) | Ø 80, Ø 100, Ø 120 |

| Size (m) Lenght x Width x Hight | 3 x 2 x 2 |

| ca. weight (t) | 3,3 - 3,7 t |

Briquette formats in

mm

mm

|

|

|

| Ø 80 | Ø 100 | Ø 120 |

|---|

Downloads

Download free informational material here

[Translate to Englisch:] Flyer Schleifschlamm [Translate to Englisch:] RUF Unternehmensbroschüre [Translate to Englisch:] Formular kostenfreie ProbeverpressungRequest a free test pressingDownload information sheet "pressing test"

zurück