Wood briquettes packed full of energy Konolt manages its energy output using RUF briquetting machinery

Konolt manages its energy output using RUF briquetting machinery

Timber processors Konold are improving their energy balance with the help of their RUF briquetting machine. Wood waste is being pressed into briquettes to create a uniform combustible material. The heat they produce is then used for process heating and to heat their premises, with the residual heat being used to generate electricity. Konold Härtsfelder Holzindustrie GmbH values this improved combustion material because it is so easy to manage during the energy release process.

Today more than ever, it makes good business sense to recover energy from production residues. Konold is a medium-sized door manufacturer based in Dischingen-Katzenstein in Swabia, southern Germany. In RUF briquetting machinery, the company has found an effective solution to the question of how to turn dusty waste materials created during the production process into briquettes which can then be fed back into the energy cycle. Konold doors are manufactured with great attention to detail and their makers have many years' experience when it comes to working with wood. Their expert staff select the veneers and manufacture the doors with great precision and skill. More unusual types of doors can also be produced on a one-off basis. Special sizes, unusual shapes and individual designs can be manufactured and delivered very quickly.

It is this flexibility and Konold's openness to new markets that has turned a wheelwright company founded in 1900 into a flourishing business with 141 employees. The company has always been a family-run business. Directors Albert and Konrad Konold and their sons Jürgen and Markus concentrate solely on doors and how to manufacture them in the best possible way. They mainly specialise in tailor-made products, because, according to Konold, the demand for mass-produced doors has died off. Now they have to focus on lowering costs and improving the efficiency of their production processes in order to maintain and grow their market share. So at Konold they are proud to supply their customers with top-quality, tailor-made products. Their main focus is on how the wood is processed.

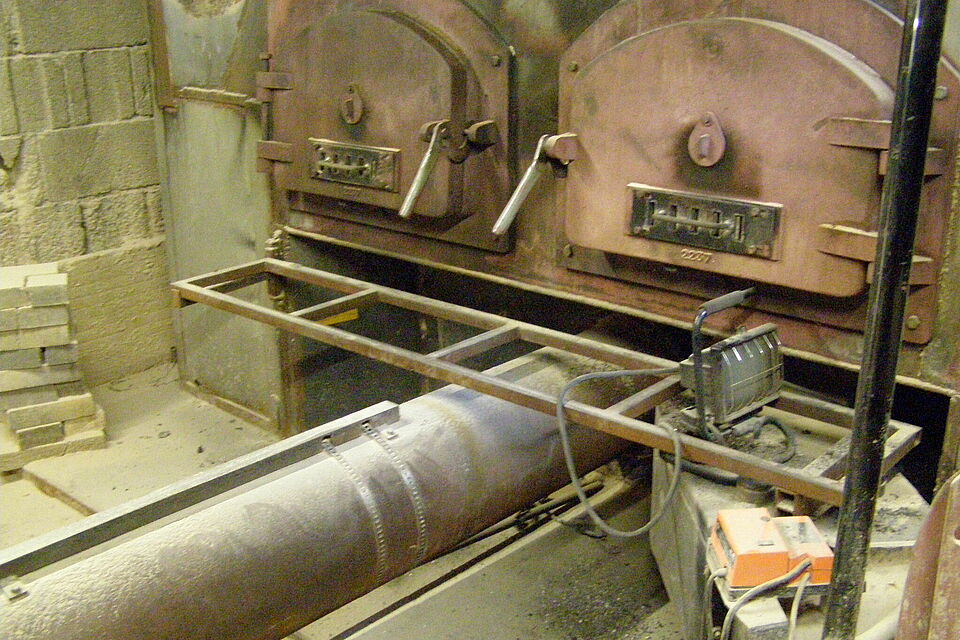

The RUF 400 briquetting machine

The RUF 400 briquetting press is equipped with a 22 kW three-phase motor in the IE2 efficiency class and, depending on material, it can achieve an output of up to 400 kg per hour. Its IP 54 protection rating makes it ideal for use in dusty environments. The press works on the single press principle, so each briquette is pressed individually under high pressure without the use of any additives or synthetic binding agents. In this way it remains a natural product and complies with the DIN 51731 and ÖNorm M 7135 environmental standards. The briquettes can be handled immediately, as they are lukewarm when they come out of the machine.

Generating energy from sander dust and woodchips

Konold Härtsfelder Holzindustrie GmbH produces around 10,000 doors and blanks each month, along with 7,000 door frames. Before buying their briquetting machine, 700 kgs per hour of sander dust, woodchips and other wood waste were loaded directly into a boiler without any kind of processing. This boiler operated 13 hours a day, depending on the amount of heat required. The steam it produced heated the 21,000 m² factory buildings, and a steam turbine generated 1 MW of electricity. The variable moisture content of the woodchips affected their energy content, resulting in fluctuations of up to 150 KW in the electricity they generated. On top of this, there was the difficulty of controlling the combustion because of the dust.

The Konolds realised that, if they wanted to resolve this problem and have achieve more controlled combustion, they would have to compress the wood dust using briquetting equipment. So Jürgen Konold began looking for a suitable local supplier. He says: "We were determined to source machinery and the other items we needed from Germany". The door experts found the right partner in RUF GmbH & Co. KG, based in Zaisertshofen. They were particularly impressed by the excellent and speedy customer service they received when placing their order with RUF.

Greater efficiency using RUF briquettes

Customer and supplier got together to carry out joint tests using pillow-shaped briquettes. The results showed that the customer needed briquettes measuring no more than 75 mm in height in order to guarantee a smooth operation. They found the right solution, and Jürgen Konold is happy to say that the RUF 400 briquetting machine has been running "like clockwork" since mid-January 2011.

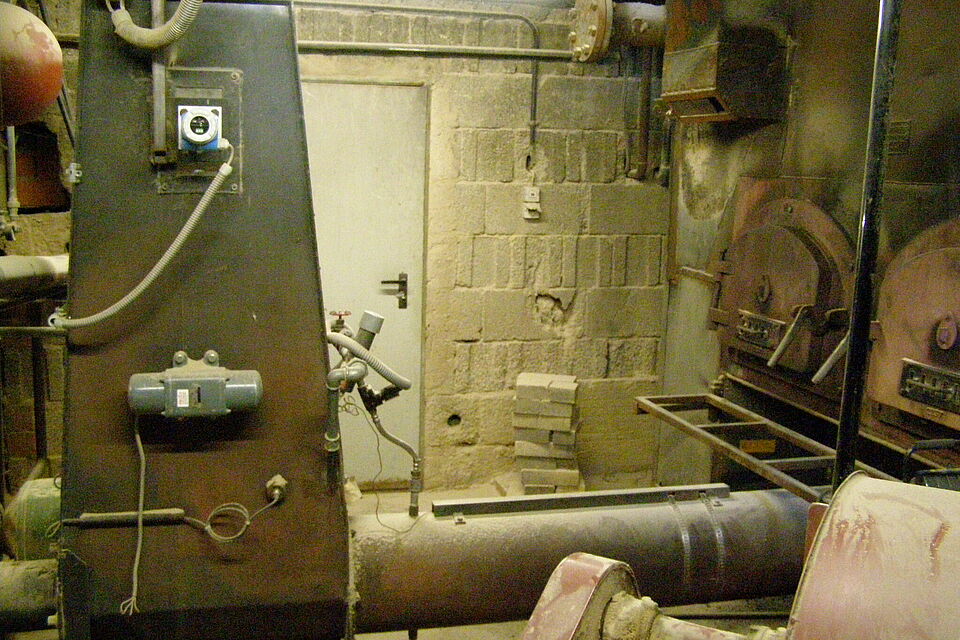

The mainly fine, dusty material for briquetting is fed in to the machine from a silo. The compressed, pillow-shaped briquettes are discharged and broken into two by a breaking device. These pieces then drop down a steep chute onto a drag conveyor, where they are combined with woodchips from an outdoor wood cutting machine. The drag conveyor carries this mixture of woodchips and briquettes to a screw conveyor that then transports them to a boiler with an underfeed furnace.

The briquettes have a clearly-defined and uniform energy content, allowing much cleaner and more even combustion at higher average firing temperatures. This has a positive effect on the steam produced and the resulting generation of energy. According to Konold, the fluctuations they were experiencing previously have been largely eliminated.

The Konold family are also very happy with their investment for environmental reasons. They say that their electricity generation is much more stable now that they the damp woodchips are fed into the boiler along with dry briquette pieces. The steam turbine is now operating much more efficiently, and produces much less ash. "The RUF briquetting machine has really improved the quality of the combustion material", says Jürgen Konold. And the uncontrolled burn produced by the dusty material is now a thing of the past.

Briquetting also has other advantages: because the price of buying woodchips has soared over recent times, Konold is now even more keen to use briquettes made from fine wood waste. In this way they hope to achieve even greater efficiency. The company's management are considering the possibility of collecting wood waste locally in order to turn it into briquettes and use it to generate energy. "It's really easy to control the use of briquettes", says Jürgen Konold, "and it means we don't have to buy as many woodchips, which are getting more and more expensive". This would certainly be a possibility, as the RUF 400 still has plenty of capacity and can handle larger quantities. In this way Konold can do their bit for the environment by recycling wood waste and turning it into energy.