The right hopper for every briquetting challenge

Ruf Maschinenbau offers a wide range of feeders

How to briquette metal chips properly not only depends on the press. Also the right hopper and feeder are crucial to the reliability of the process. RUF Maschinenbau has the right solution for all needs.

Many companies are recognising the growing importance of briquetting metal chips. This not only simplifies greatly their handling and logistics, but also boosts their value as a secondary resource. Important here, in addition to a suitable briquetter, is the right hopper and integrated feeder.

These peripheral solutions too are being developed and refined by the RUF Group in Zaisertshofen alongside its quality briquetting presses. The product portfolio now extends to a great many variants covering the whole range of foreseeable capacities, input stock, and space requirements. And these can be fitted with various feeder and hopper geometries and sizes.

In the first instance, the briquetting specialist distinguishes between two variants:

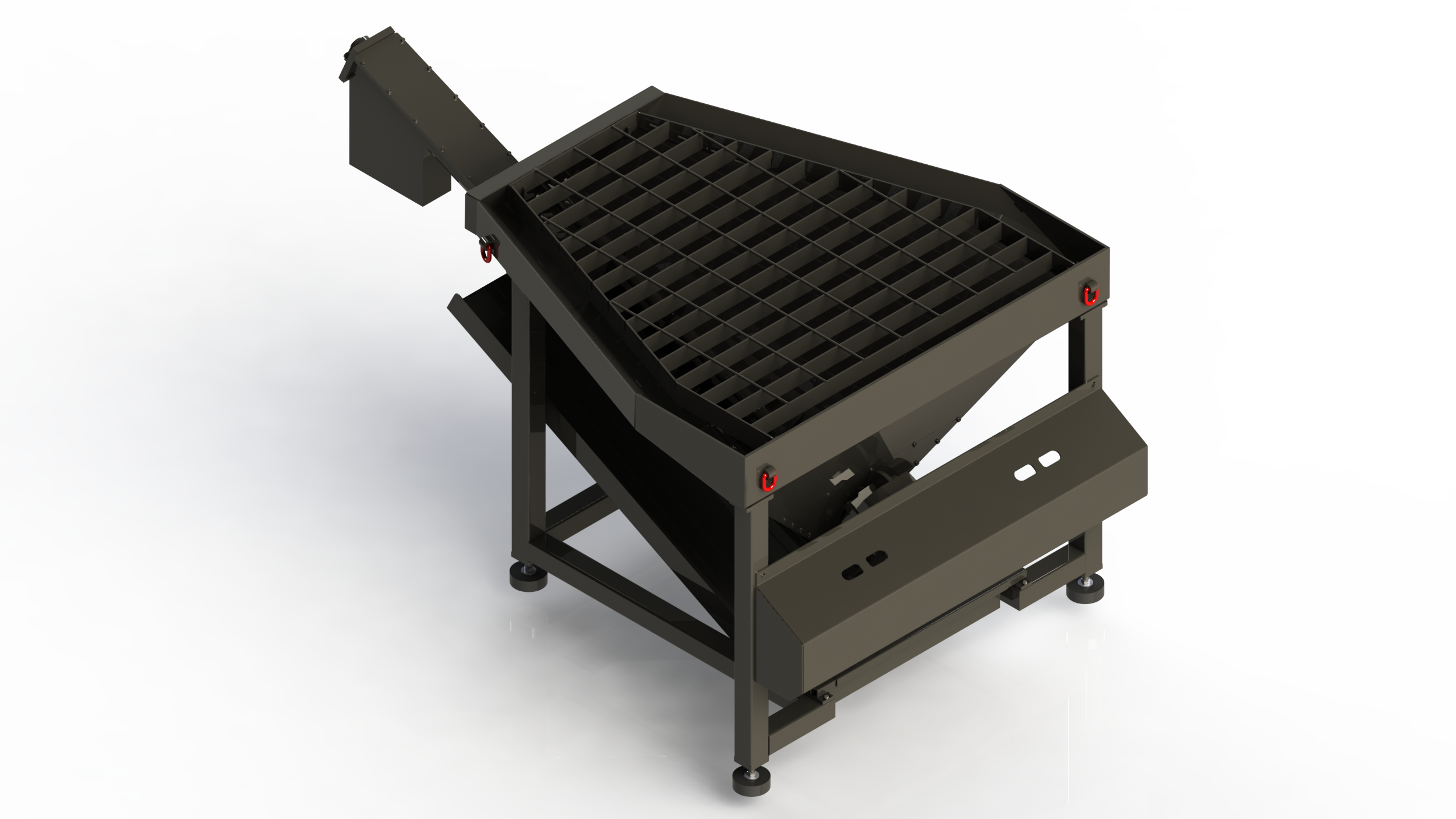

1. Hopper with horizontal screw of mostly 2 m³ capacity running parallel to the floor.

2. Floor chips hopper with variable, inclined screw feeder of 2–5 m³ capacity.

The portfolio also offers silo conveyors. These chip transporters take the form of hinged belts. Available with capacities of 2–5 m³ they are used in a number of cases for aluminium chips.

One special variant of 6 m³ capacity combines a screw and a hinged belt feeder. These are designed for heavy input stock.

In determining the right hopper and feeder for each and every case, RUF Sales Manager Andreas Jessberger explains that three key questions must first be answered: What is the volume of chips accumulating? What is the physical environment, i.e. how much headroom and area is available? What kind of chips are produced in what bulk density, and are they flowable? Assisted by the answers, the briquetting experts at RUF never fail to select the most suitable hopper including chip feeder.

Low-cost standard hoppers

The RUF portfolio includes a low-cost solution in the form of a standard hopper featuring a horizontal screw and set in a base frame. This can provide the optimal solution when the local headroom permits the hopper to be filled easily in its base frame.

Then only the type of chips needs to be clarified. Are they flowable, i.e. heavy and short, as is often the case in cast iron and steel machining? If so, RUF recommends a simple screw for the feed. If, on the other hand, the chips are light and/or tangle easily, they will need an additional agitator. Alternatively, these cases can also be processed with two parallel screws.

For minimal quantities of flowable chips, RUF can provide an interesting extension to its standard hopper for applications close to floor level. This option takes the form of an additional hinged belt that conveys the chips upwards into the briquetting system.

Highly versatile floor chips hoppers

The so called floor chips hoppers are considerably more flexible than the standard models and are always easy to charge. According to RUF Sales Manager Jessberger, these are the most common types in practice, for a very good reason. “They need little headroom, and their wide range of capacities and feeders make them ideal for virtually all needs,” explained the engineer.

The crucial difference from the standard hoppers lies in the inclined screw. This conveys the chips from below to the height needed to supply the briquetting system. Whether a single or double screw is recommended depends primarily on the supplied chips. And here too: If the chips are flowable, i.e. heavy and short, a single feeder screw proves adequate. Otherwise, for instance in the case of light aluminium chips of low flowability, an additional agitator becomes necessary, or alternatively a double screw must be used for the transport.

Andreas Jessberger explains the physically simple, yet effective trick with the double screw: “If only the one screw is fitted, the bottom discharge is considerably narrower than the hopper’s receiving aperture. In other words, the hopper walls converge abruptly. Lighter, longer chips often remain on these. Arching is the result. When two screws are fitted, especially such with larger diameters, the hopper’s discharge aperture is so large that the walls converge only gradually. Chips then always drop into the screw channel, including those that are light and tangle easily. Arching is therefore eliminated.”

Drip pan with slurp pump for wet chips

These criteria then serve as a reliable basis for the setup and dimensioning of hopper and feeders. In addition, a working solution also depends on whether the supplied chips are dry or wet. In the latter case, drip pans with slurp pumps are important for transporting away the extracted coolants.

Equally important is the hardness of the input stock. If the briquetting systems are supplied with soft metals like aluminium, standard screws of structural steel prove adequate. If, though, the hopper is charged with harder, abrasive steel chips, briquetting expert Andreas Jessberger recommends screws of Hardox.

If the input stock is grinding sludge, RUF goes a step further: robots weld on its screws a 5 mm thick carbide lining. Jessberger explains: “This armour lining of tungsten steel serves to boost the screws’ service lives, even under the highly abrasive conditions of grinding sludge.”