Customer satisfaction has always been our top priority. We take your individual requirements into account right from the planning and construction stage. We are also there for you when your RUF briquette press has (long) left our site. Our expert RUF service team offers you support by telephone or on site from the time of purchase of the machine throughout the entire lifecycle. We personally take care of maintenance, servicing, overhaul, upgrading or repairing your briquette press and ensure a trouble-free operation – no matter how old your system is.

Your benefits

- More than 90% parts availability in stock

- Parts available for all RUF presses ever built

- Express delivery in very short time available worldwide

- Fast response times for maintenance & repair

- Free and non-binding test pressing

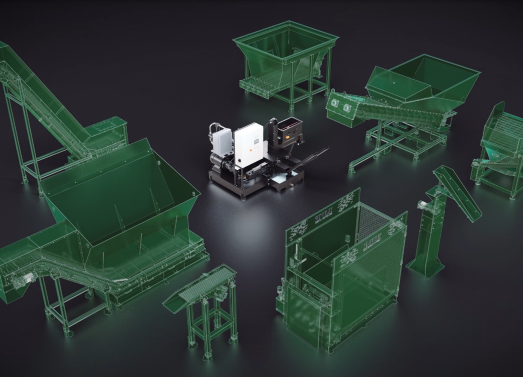

- Rental service for our systems