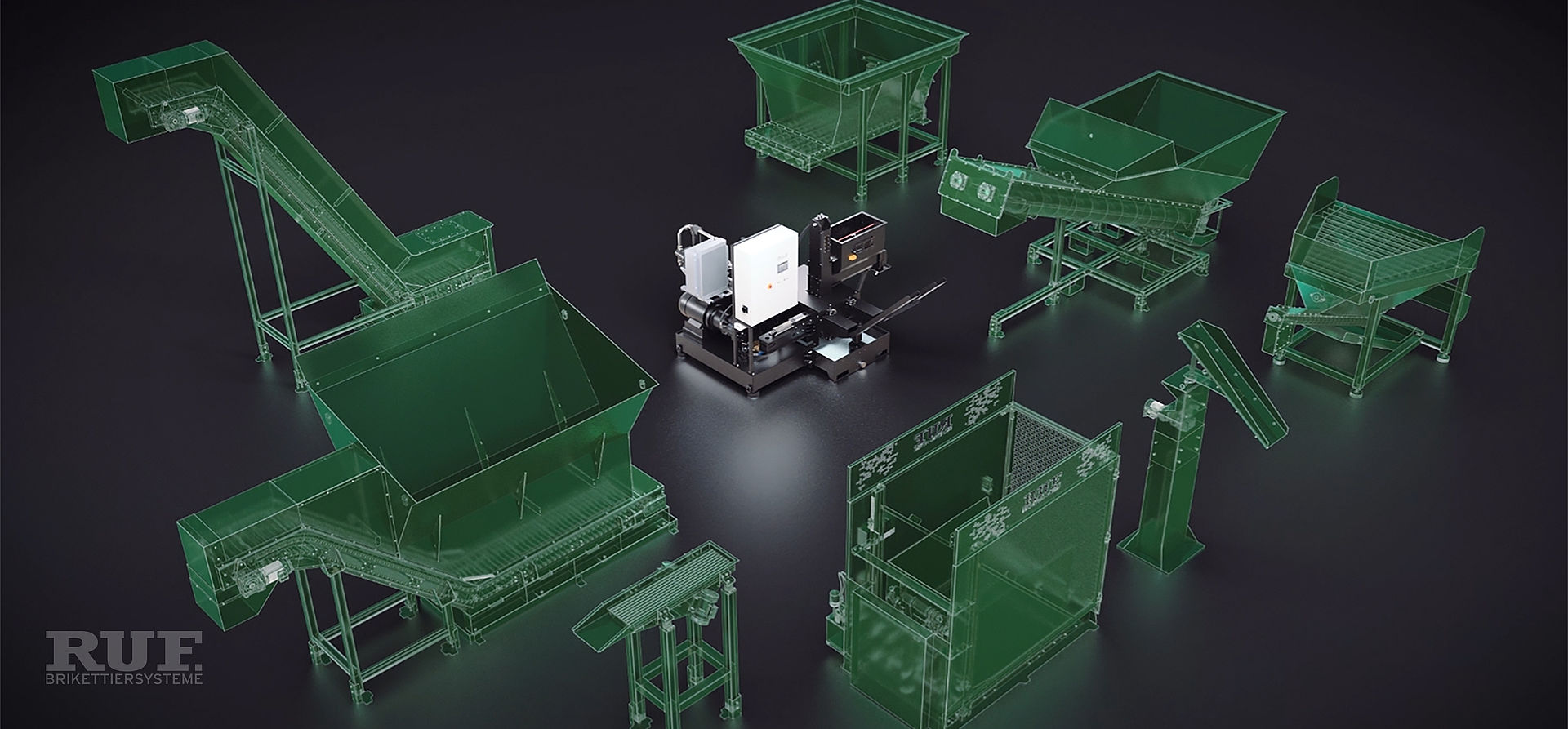

RUF peripheral equipment Optimised material flow for fully-integrated briquetting lines

In addition to briquette presses for a wide variety of materials, RUF builds and manufactures additional peripheral equipment and can therefore offer solutions for complete briquetting lines. The flow of material can be optimised and automated with the help of our various peripheral devices, such as chip conveyors, feed hoppers, silos or lifting and tipping devices. All of our peripheral equipment can be incorporated into existing production lines. RUF-periphery will be sold in combination with a briquetting system.

Z-shaped conveyor

RUF conveyors can be used to automate material feed or briquette transport in the metal or wood processing industries and in the recycling sector. With these conveyors, the chips or briquettes can be transported automatically to the briquetting machine hopper or the collection container. The briquette or chip conveyor can easily be incorporated into existing production lines.

Lifting and tipping device

Our RUF lifting devices or lifting and tipping devices are used for simple material feed with the chip cart/container. We offer solutions individually tailored to specific requirements and production environments, depending on ceiling height, required load capacity or stipulated safety equipment.

Oscillating conveyor channel

We offer oscillating conveyor channels for various applications in the metalwork sector to convey the bulk material before briquetting and to sort it according to chip size. It is also possible to incorporate these channels into existing production lines.

Chip hopper

Our chip hopper initially acts as a collecting point for the chips that are produced. Worm conveyors can then ensure that the chips are conveyed directly to the briquetting machine. Sensor detection in the hopper can ensure fully automatic feeding of the briquetting machine.

![[Translate to Englisch:] RUF Z-Förderer](/fileadmin/_processed_/0/0/csm_RUF-Z-Foerderer-1_17b52776a1.jpg)

![[Translate to Englisch:] RUF Z-Förderer](/fileadmin/_processed_/9/2/csm_RUF-Z-Foerderer-2_cacc2f0065.jpg)

![[Translate to Englisch:] RUF Z-Förderer](/fileadmin/_processed_/a/e/csm_RUF-Z-Foerderer-3_159dbca2c7.jpg)

![[Translate to Englisch:] RUF Hebe-Kipp-Gerät](/fileadmin/_processed_/9/b/csm_RUF-Hebe-Kipp-Geraet-1_b228a13b8c.jpg)

![[Translate to Englisch:] RUF Hebe-Kipp-Gerät](/fileadmin/_processed_/f/6/csm_RUF-Hebe-Kipp-Geraet-2_09ff39f38a.jpg)

![[Translate to Englisch:] RUF Hebe-Kipp-Gerät](/fileadmin/_processed_/8/7/csm_RUF-Hebe-Kipp-Geraet-3_89ed5a9817.jpg)

![[Translate to Englisch:] RUF Hebe-Kipp-Gerät](/fileadmin/_processed_/2/0/csm_RUF-Hebe-Kipp-Geraet-4_87dab2b5d2.jpg)

![[Translate to Englisch:] RUF Hebe-Kipp-Gerät](/fileadmin/_processed_/c/9/csm_RUF-Hebe-Kipp-Geraet-5_e109e18749.jpg)

![[Translate to Englisch:] RUF Schwingförderrinne](/fileadmin/_processed_/d/c/csm_RUF-Schwingfoerderrinne-1_4bf7849125.jpg)

![[Translate to Englisch:] RUF Schwingförderrinne](/fileadmin/_processed_/9/2/csm_RUF-Schwingfoerderrinne-2_bbd0fc46cc.jpg)

![[Translate to Englisch:] RUF Schwingförderrinne](/fileadmin/_processed_/8/4/csm_RUF-Schwingfoerderrinne-3_35792634c5.jpg)

![[Translate to Englisch:] RUF Spänetrichter](/fileadmin/_processed_/0/3/csm_RUF-Bodenspaenetrichter-1_309383b9fc.jpg)

![[Translate to Englisch:] RUF Spänetrichter](/fileadmin/_processed_/5/8/csm_RUF-Bodenspaenetrichter-2_59ccebfa63.jpg)

![[Translate to Englisch:] RUF Spänetrichter](/fileadmin/_processed_/d/4/csm_RUF-Bodenspaenetrichter-3_2652f56635.jpg)

![[Translate to Englisch:] RUF Spänetrichter](/fileadmin/_processed_/d/c/csm_RUF-Bodenspaenetrichter-4_517b2cfd74.jpg)

![[Translate to Englisch:] RUF Spänetrichter](/fileadmin/_processed_/e/b/csm_RUF-Bodenspaenetrichter-5_72802d3d04.jpg)

![[Translate to Englisch:] RUF Spänetrichter](/fileadmin/_processed_/f/5/csm_RUF-Bodenspaenetrichter-6_60b89b4334.jpg)