Maximum efficiency in aluminium production RUF briquetting systems increase the value of aluminium chips at Uponor Rohrsysteme GmbH

The production of aluminium pressing bushes designed for the reliable sealing of pipe unions involves cutting operations that waste nearly 80% of the raw material. As a measure to maximise the yield of this valuable material, the pipe specialist Uponor has been running RUF briquetting systems in its production since 2005. According to WCO Local Coordinator Gerart Oppelt, this investment had paid off after just nine months.

Uponor ranks among the world’s largest manufacturers of plastic pipe systems for HVAC and servicing installations. Yet not only high-quality organic polymers are important to this company. Equally vital are various engineering metals that form part of so called multilayer composite piping (of plastic and aluminium) and, specifically, fittings. The Uponor location specialising in this is based in Hassfurt, Lower Franconia. There, about 120 employees produce each year an average 25 million brass fittings assembled with aluminium pressing bushes, plastic rings, and O rings.

The production locations are in constant competition with external fittings providers and so must maintain their productivity at the highest level in all areas. This continuous improvement process is the responsibility of Gerald Oppelt. Backed by many years of experience in Hassfurt, this production manager and head of production optimisation has a quite specific target in mind: the cost leadership of his fittings production. Oppert explains: “High quality is the be-all and end-all in our sector. Orders then hinge on factors like delivery reliability and price. And exactly that is the target of our unceasing endeavours. In 2009 we even introduced a three-year plan that was to help us maximise our internal OEE metric for productivity by 2012.”

Yet maximised cost effectiveness had adopted a top priority at the Hassfurt plant long before this three-year plan. This led, to name but one measure, to the integration of aluminium production in late 2004. The company’s intention was to produce itself the alloy pressing bushes at a lower price than it had been paying so far for external deliveries. This production area centres on two eight-axis automatic bar lathes that deliver 16 mm and 20 mm pressing bushes at 1.7 second intervals. In three-shift mode, the average daily output amounts to about 50,000 pieces per machine.

Briquetting system classed as the only cost-effective solution

This “turbo workcycling” involves cutting operations that waste nearly 80% of the quality aluminium (AlMg4.5Mn0.7). All in all, about 125 tonnes of oily, long continuous chips are left over every year from the approx 160 tonnes of aluminium input stock. It became clear to the production managers and the employees that they had to find a practicable solution for this waste quantity, and soon. Accordingly, the then head of production formed a project group to tackle this issue.

The object was to reduce the chip volume and to extract the oily liquid from the chips, which would otherwise have been treated as special waste since no foundry accepts wet input stock. The most promising solutions were offered by two implementations. The first involved a combined crusher and centrifuge, the other a high quality briquetting system. Ultimately, only the one proved to be economically feasible – the briquetting system. Production Optimiser Oppelt summed up the crucial factors: “Foundries pay virtually nothing for wet chips. On the other hand, briquettes take up far less space, and the overall costs for briquetting systems are lower.”

The Uponor project group’s continued researches soon uncovered a suitable supplier, the Zaisertshofen company RUF, leader in innovative briquetting technology. Gerald Oppelt explains: “We scoured the internet and the trade media. In addition, we asked for recommendations from our partners like Knoll Maschinenbau, our preferred specialist for filter systems. The name RUF was mentioned time and time again. Following the experience I’ve gained, I can only confirm that.” An inspection of the systems in Zaisertshofen in late 2004 and a number of test runs served to convince the Uponor delegation unreservedly, and the order was placed for a RUF 4 /3700/60x40.

RUF 4 investment paid off after nine months

Punctually on the agreed delivery date, on 2 January 2005, the RUF 4 arrived in the Uponor aluminium machining area in Hassfurt – precisely two weeks after the lathes had been commissioned. Oppelt recalled that those two weeks without briquetting press were not easy ones: “The huge volume of chips accumulating in this period took up a lot of space we didn’t have. So we were very happy when RUF delivered the machine on time and commissioned it in just half a day. Since then it has been running unattended, reliably and continuously, in three-shift mode five and, if necessary, six days a week. Ultimately and accordingly, the briquetting press paid off within just nine months.” Following this encouraging experience, Uponor purchased in 2007 an additional RUF 4, and now each automatic lathe has its own briquetting press. This has served to simplify further the production processes and raise overall productivity.

The two RUF 4 units are midsized machines that can process the most diverse metals and are ideal for compressing aluminium chips. Thanks to the screws installed in the feed hopper, the continuous chips can be supplied directly and at a high rate from the automatic lathes to the briquetting machine. There they are compressed under 300 bar generated by a 4 kW hydraulic motor and formed into rectangular briquettes under a specific pressure of 2304 kg/cm². Measuring 60 mm wide and 60 mm high, they can be handled easily. The volume of the input aluminium is reduced to as much as one twentieth, depending on the chip geometry.

Valuable aluminium briquettes and recovered lubricating oil

Briquetted aluminium (AlMg4.5Mn0.7) fetches a considerably higher price on the market than bulk chips. Oppelt reported about EUR 1.1 per kilogram, which his company is being offered at present. The decisive factors are the briquettes’ high density and their correspondingly low residual moisture content of about 4%.

Yet not only the sales of compressed alloy are boosting cost effectiveness in the Hassfurt aluminium machining area. Also the lubricating oil extracted from the chips can be reused completely. Solely the 4% residual moisture in the briquette must be replenished at regular intervals. The extracted 96% passes through a Knoll filter system downstream of the RUF 4 before returning directly into the coolant circuit. In consequence, Uponor can keep its consumption of lubricating oil extremely low.

Today, Gerald Oppelt sees the two RUF presses as “little Midases” that can turn worthless wet chips into valuable aluminium briquettes. At the same time, this production specialist continued, the machines are absolutely easycare. Only once a month does an operator have to perform minor maintenance, and once a year a RUF employee comes from aftersales services.

Uponor GmbH of Hassfurt

is a 120-employee subsidiary of the Finnish Uponor Group of Vantaa whose 3300 employees worldwide generate a turnover of approx EUR 730 million. The Group produces plastic pipe systems for gas, water, and sewage installations as well as for heating/cooling, service water heating, and ventilation/AC installations. The products are installed in private and commercial buildings. It also offers solutions for private and community water supply, water disposal, and gas supply infrastructures. The core competency embodied by Uponor GmbH of Hassfurt lies in the manufacture of the most diverse pipe connectors (so called fittings) and their accessories.

Uponor GmbH

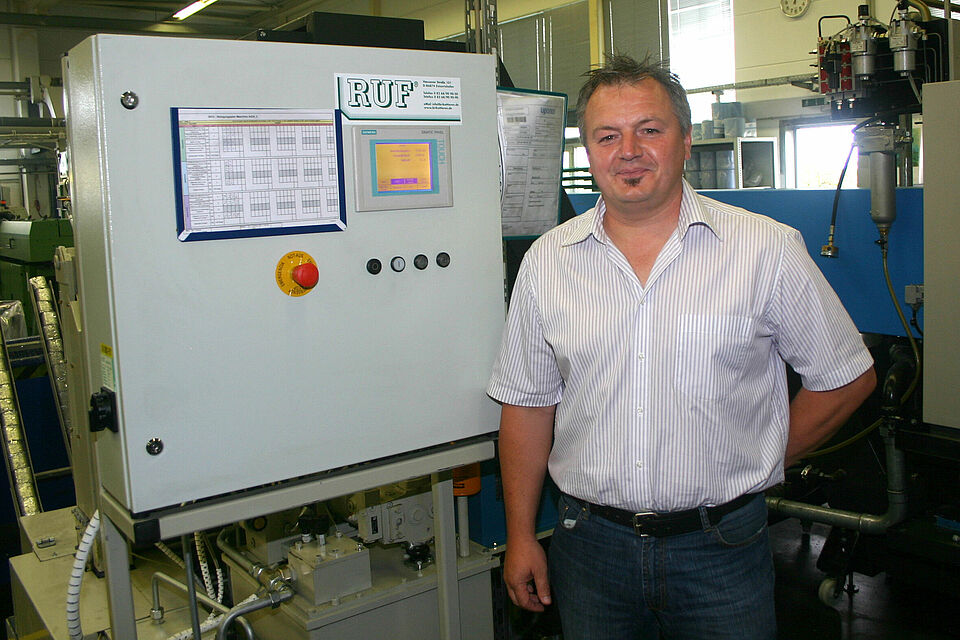

Gerald Oppelt

Industriestr. 56

97437 Haßfurt

+49 9521 690 482

gerald.oppelt@uponor.de

RUF GmbH & Co. KG

Roland Ruf

Hausener Str. 101

86874 Zaisertshofen

Tel: 08268 9090-20

Fax: 08268 909090

info@brikettieren.de

www.brikettieren.de