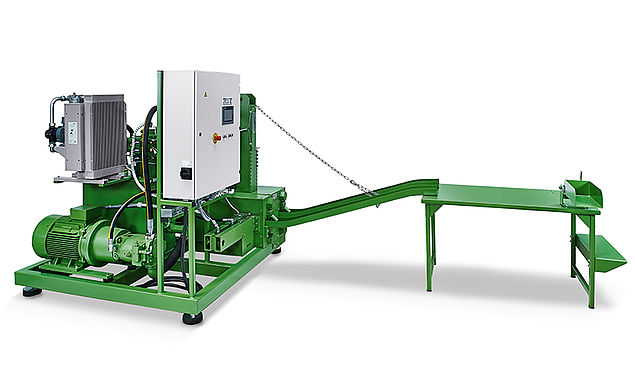

RUF LIGNUM Classic Standardised briquetting press for wood │ with or without packaging table

The advantages for you at a glance:

- Fully automatic 24h operation possible

- Long service life

- Low maintenance costs

- Compact construction

- Direct incorporation into existing production facilities possible

- More than 35 years’ experience

Briquetting wood residues – earning additional revenue

Die The RUF LIGNUM Classic wood briquette press is ideally suited to briquetting medium quantities of wood chips that are produced as a waste product of the wood processing industry. Thanks to the process of briquetting, additional revenue can be earned and storage and transport costs are cut. Another advantage can be found in the flexibility of our wood briquette presses. They can press various grain sizes of material into high-quality briquettes, completely without the use of binding agents. As a result, as a valuable source of energy, RUF briquettes actually have a higher utilisation value and an optimum CO2 balance. Our LIGNUM range also performs well in terms of having a high level of energy efficiency and a low level of wear and tear, thanks to our innovative RUF hydraulics.

Technical data RUF LIGNUM Classic

| Max. throughput rate (kg/h) Wood | 410 |

|---|---|

| Power (kW) | 30 |

| spec. Pressure, max. (kg/cm²) | 1700 |

| briquette formats (mm) | 150x60 |

| Size (m) Lenght x Width x Hight | 2,1 x 1,9 x 2,0 |

| ca. weight (t) | 3,3 t |

Briquette formats in

mm

mm

|

| 150x60 |

|---|

Downloads

Download free informational material here

[Translate to Englisch:] RUF Flyer LIGNUM [Translate to Englisch:] RUF UnternehmensbroschüreRequest a free test pressingDownload information sheet "pressing test"

zurück