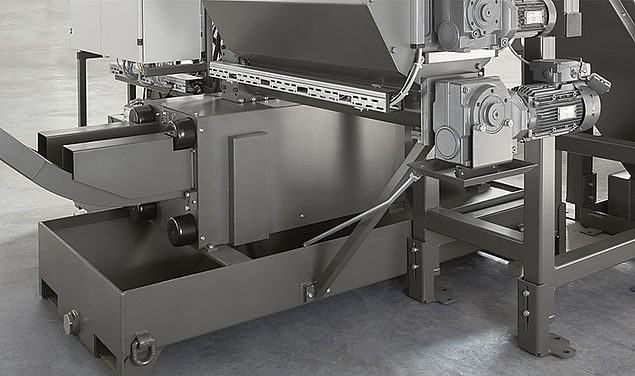

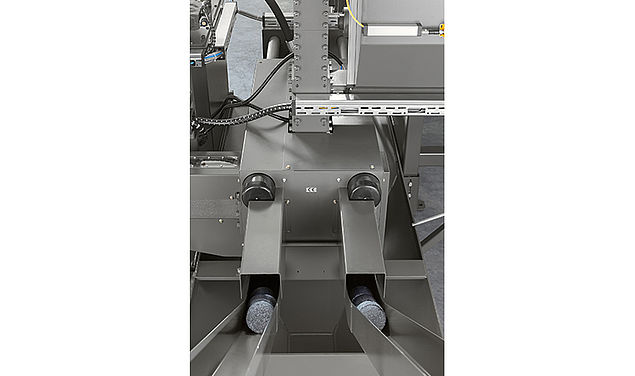

RUF 18,5-55 Briquette presses for larger quantities of metallic residues

The advantages for you at a glance:

- For larger quantities of metal chips

- Short amortisation period

- Recovery of cooling lubricants

- Fully automatic 24h operation possible

- Long service life & low maintenance requirements

Added value through the briquetting of metallic residues

Depending on the starting material, our metal presses in the RUF 18.5-55 series achieve a maximum throughput of up to 2,800 kg/hour and are thus ideally suited to briquetting larger quantities of metal chips. Through the briquetting process, you not only reduce transport, storage and handling costs, but also earn higher revenues. In addition, expensive cooling lubricants can be recovered and maybe even reused, depending on their properties. Whether you are dealing with aluminium, steel, brass, copper, titanium or any other metallic residues – RUF offers individually tailored briquetting solutions that will precisely match your individual requirements.

Technical data RUF 18,5-55

| Max. throughput rate (kg/h) Aluminium | 300-1.600 |

|---|---|

| Max. throughput rate (kg/h) Brass, bronze, cooper | 450-2.700 |

| Max. throughput rate (kg/h) Magnesium | 100-550 |

| Max. throughput rate (kg/h) Steel & Castings | 350-2.800 |

| Max. throughput rate (kg/h) Titan | 300-1.000 |

| Power (kW) | 18,5, 30, 55 |

| spec. Pressure, max. (kg/cm²) | 1.700 - 5.000 |

| briquette formats (mm) | 150x75, 150x120, Ø80, Ø100, Ø120 |

| Size (m) Lenght x Width x Hight | ca. 2,9 x 2,4 x 2,2 |

| ca. weight (t) | 4,6 - 6,5 t |

Briquette formats in

mm

mm

|

|

|

|

|

| Ø100 | Ø120 | Ø80 | 150x120 | 150x75 |

|---|

Downloads

Download free informational material here

[Translate to Englisch:] Flyer Metall [Translate to Englisch:] RUF Unternehmensbroschüre [Translate to Englisch:] Formular kostenfreie ProbeverpressungRequest a free test pressingDownload information sheet "pressing test"

zurück